By ThinkReliability Staff

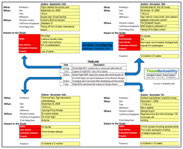

The first step of the Cause Mapping strategy of root cause analysis is to define the problem with respect to the organization’s goals. In order to do this, you need to know what an organization’s goals are. While we provide Cause Mapping root cause analysis templates that will give you an idea of where to start, your organization may wish to personalize their investigations so that they correspond to your particular goals.

To define your organization’s goals, try to imagine a perfect day for your organization. No matter what industry you’re in, that perfect day doesn’t include anyone getting hurt or killed. This is the safety goal. However, if your organization regularly is responsible for the health and welfare of people other than your employees, you may wish to have more than one category of safety. For example, a hospital may have both “patient safety” and “employee safety” goals. A public school may have “student safety” and “employee safety” goals.

Another goal generally common to all industries is the goal of not impacting the environment. However, some industries have a base level of environmental impact, so their goal might be to not surpass that level rather than having no impact. Environmental impacts usually result from leaks or spills of any material other than water, but may also result from improper storage or disposal of hazardous material.

Some organizations may have as a goal to meet regulatory requirements. If an organization has an OSHA (Occupational Safety and Health Administration) reportable injury, this is an impact to the “Regulatory Compliance” goal. Organizations may also have a “Compliance” goal if they are subject to another governing body, such as a trade group or an external accreditation.

Organizations usually exist to provide either products, services, or both. If an organization provides products, a goal of that organization may be to get a set amount of products produced and delivered on a certain schedule. We call this the “Production/Schedule” goal. An organization that provides services wants to ensure that its customers are satisfied with the services they provide. This is the “customer service” goal. Many organizations will use both goals to define a problem.

Another area of concern for almost all organizations is cost. An incident that requires additional labor, rework, or lost product results in unplanned costs for the organization. We call this goal the “material and labor goal”. If an incident results in many costs, it’s possible to itemize them within the problem outline. Quantifying all the costs associated with an incident can help prioritize which incidents require the most immediate attention. It also provides a bound for the cost of solutions – installing a $100,000 machine to solve an infrequent $20,000 problem doesn’t make sense. (Of course, for incidents that involve impacts that can’t be easily quantified – human safety, regulatory requirements, customer service, etc. – these impacts must be considered above and beyond the “cost” of the incident.)

Once you’ve determined all of the goals that are meaningful to your organization, you’re ready to make an outline for the first step of the Cause Mapping method of root cause analysis – define the problem. But what order do you put the goals in? Generally, the goals go in order from most to least important. The safety goal is almost always at the top. Your organization’s mission statement is an excellent resource to determine the order of the goals. Ideally, they’ll follow along with your mission statement, with any goals not specifically called out (such as the “material and labor” goal) listed below. It’s also possible to use a different order so that the biggest impacts from an incident are listed at the top. However, your organization may prefer to always use the same order for consistency.

If an incident resulted in no impact to one of your organization’s goals, don’t delete the goal from the problem outline. Instead, write “N/A” next to the goal. That way, it’s clear that the goal was considered but it was determined that there was no impact. Deleting the goal may lead others to believe that it’s no longer a goal of the organization!

Check out our examples to see a problem definition in action!

ThinkReliability has specialists who can solve all types of problems. We investigate errors, defects, failures, losses, outages and incidents in a wide variety of industries. Contact us for investigation services and root cause analysis training.

By Kim Smiley

Eurostar, the operator of the train, has stated that the failure of the trains were caused by an electrical failure due to condensation from snow that was able to enter the snow screens protecting the engine and higher temperatures within the tunnel than outside. Unseasonably cold weather was believed to cause finer, lighter snow than usual, which was able to enter the screens.

Eurostar, the operator of the train, has stated that the failure of the trains were caused by an electrical failure due to condensation from snow that was able to enter the snow screens protecting the engine and higher temperatures within the tunnel than outside. Unseasonably cold weather was believed to cause finer, lighter snow than usual, which was able to enter the screens.