By Kim Smiley

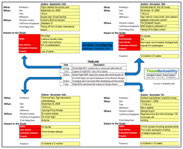

High-speed train service in the Channel Tunnel (connecting Britain, France and Belgium) resumed partially on Tuesday, December 22, 2009 after a complete stoppage that began Friday, December 18th when five trains failed inside the tunnel.

Eurostar, the operator of the train, has stated that the failure of the trains were caused by an electrical failure due to condensation from snow that was able to enter the snow screens protecting the engine and higher temperatures within the tunnel than outside. Unseasonably cold weather was believed to cause finer, lighter snow than usual, which was able to enter the screens.

Eurostar, the operator of the train, has stated that the failure of the trains were caused by an electrical failure due to condensation from snow that was able to enter the snow screens protecting the engine and higher temperatures within the tunnel than outside. Unseasonably cold weather was believed to cause finer, lighter snow than usual, which was able to enter the screens.

There was a delay in rescuing the trapped passengers in the tunnel – some of whom were trapped for up to 18 hours. Responsibility for rescue lies with both the train operator and the tunnel operator, and the process for rescue obviously needs to be reviewed by both parties to determine a better course of action the next time a rescue plan is needed. Additionally, the train operator will want to review its policies based on the reports of abysmal customer service throughout the event.

Eurostar took immediate action to install finer filters on the engine intakes and trains were put back into service on Tuesday, the 22nd. The company has also stated it will reimburse passengers for the delay, but this solution will take longer to implement.

The entire root cause analysis investigation so far is shown on the downloadable PDF. A thorough root cause analysis built as a Cause Map can capture all of the causes in a simple, intuitive format that fits on one page. Even more detail can be added to this Cause Map as the analysis continues. As with any investigation the level of detail in the analysis is based on the impact of the incident on the organization’s overall goals. To view the PDF, click on “Download PDF” above.